In today's fiercely competitive global market, manufacturers are constantly seeking ways to optimize their operations, reduce costs, and enhance efficiency. The rise of Industry 4.0, driven by technologies like IoT, AI, and advanced analytics, presents unprecedented opportunities for this transformation. However, even the most sophisticated digital solutions require reliable, efficient, and cost-effective hardware. This is where gear motors step into the spotlight, offering a powerful solution for a wide range of manufacturing applications. This article explores how integrating gear motors, particularly those offered by companies like MES-Drive, can lead to significant cost reductions and efficiency improvements in modern manufacturing environments.

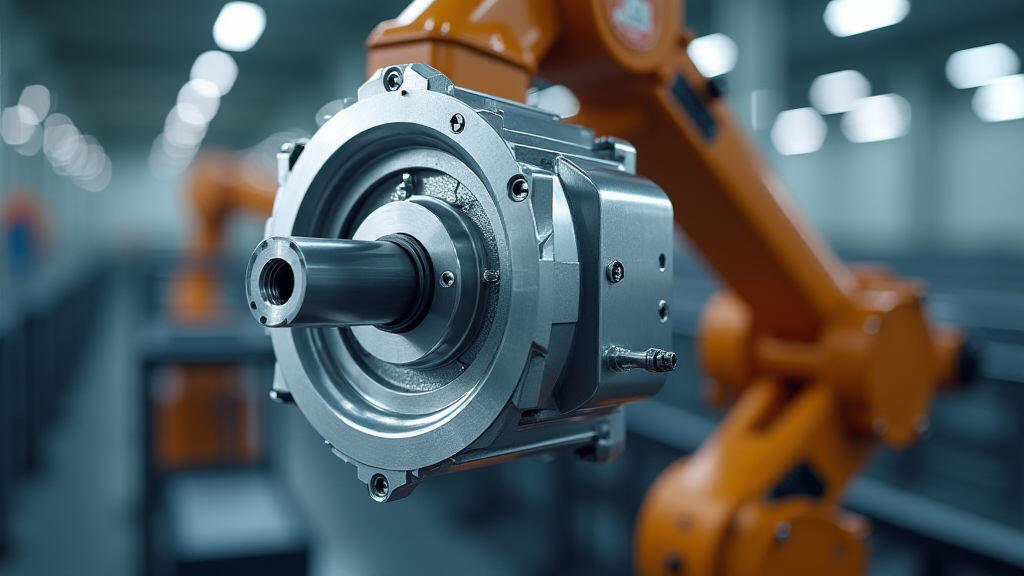

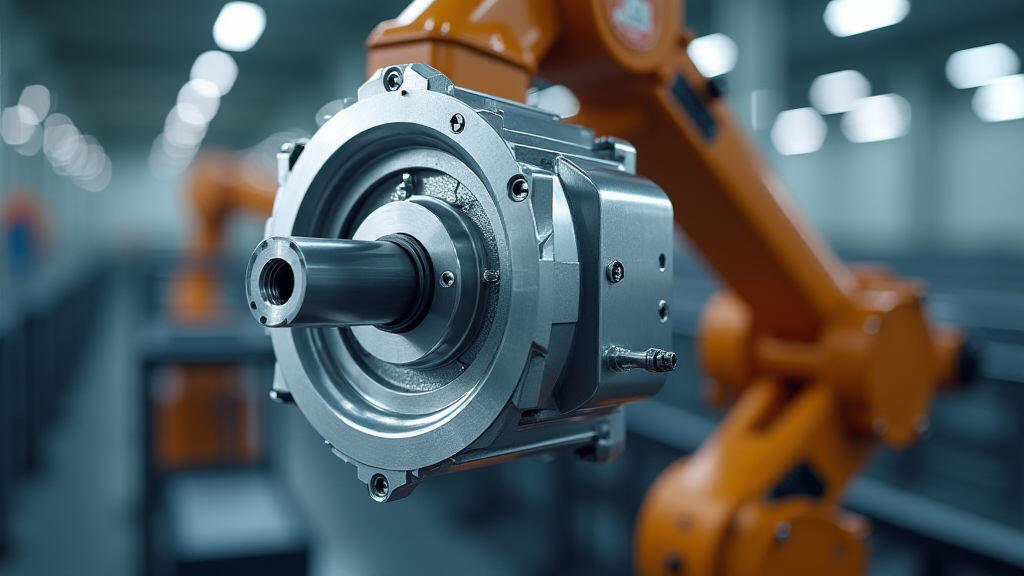

At its heart, a gear motor is a combination of a motor and a gearbox integrated into a single unit. The motor provides the rotational power, while the gearbox reduces the motor's speed and increases its torque. This is crucial for many manufacturing applications where high torque at lower speeds is required – for example, in conveyor systems, robotics, and machine tools. Unlike direct-drive systems, gear motors offer significant advantages in terms of power density, efficiency, and controllability.

The efficiency of a gear motor is a critical factor. Traditional direct-drive systems often suffer from low torque at start-up and high energy consumption. Gear motors, when properly designed and manufactured, can achieve efficiency rates exceeding 90%, translating directly into lower electricity bills and reduced operational costs. The reduction in energy consumption is particularly relevant in the face of increasing energy prices and the growing emphasis on sustainable manufacturing practices – aligning perfectly with the global push for decarbonization, a major topic of discussion at recent industry conferences.

The benefits of using gear motors extend far beyond energy savings. Here's a breakdown of how they contribute to cost reduction across various areas of manufacturing:

Beyond cost reduction, gear motors significantly improve manufacturing efficiency. Here's how:

The versatility of gear motors makes them suitable for a vast array of manufacturing applications:

The demand for gear motors is expected to continue growing in the coming years, driven by the ongoing trend towards automation, Industry 4.0, and smart manufacturing. Manufacturers are increasingly recognizing the value of investing in high-quality, efficient gear motors to improve their bottom line and stay competitive. Technologies like advanced gear designs, optimized lubrication systems, and integrated sensors are further enhancing the performance and reliability of gear motors. MES-Drive is at the forefront of this innovation, developing next-generation gear motors that are tailored to meet the evolving needs of the manufacturing industry. Specifically, MES-Drive is exploring the use of AI-powered predictive maintenance algorithms to optimize gear motor performance and minimize downtime.

The current geopolitical climate and supply chain disruptions are further emphasizing the need for reliable, domestically sourced components. Companies like MES-Drive, with a strong manufacturing presence, are well-positioned to meet this demand and provide manufacturers with a secure and resilient supply chain.

Gear motors represent a fundamental building block for modern manufacturing facilities striving for cost reduction and efficiency improvement. By offering a combination of high efficiency, reliability, and versatility, gear motors empower manufacturers to optimize their operations, reduce waste, and enhance productivity. As the manufacturing industry continues to embrace Industry 4.0 and smart manufacturing practices, the role of gear motors will only become more critical. The innovative solutions offered by companies like MES-Drive promise a future of smarter, more efficient, and more sustainable manufacturing, a crucial element for navigating the challenges and opportunities presented by the rapidly evolving global landscape.

Leave A Reply

Your email address will not be published. Required fiels are marked